Customized New Energy Battery Design Pricing Basics

All pricing secrets for your custom battery projects

When seeking a reliable new energy battery supplier, it’s natural to have several important questions. Let’s explore some of the most frequently asked questions to help you make an informed decision:

- How do I determine the cost of my custom lithium-ion battery?

- How can I identify the best battery supplier for my needs?

- How can I make the final decision on battery design?

- What is Value Engineering, and how can I study it?

While some may choose to obtain quotes from multiple suppliers and opt for the cheapest option, price alone should not be the sole determining factor. It’s important to consider other crucial aspects, such as quality, reliability, technical support, and long-term partnership potential.

In this article, we aim to provide valuable insights into the secrets of the lithium battery industry to help you navigate the decision-making process effectively. Let’s dive in and explore the essential aspects that will empower you to make an informed choice for your energy storage needs.

4 Main Parts of Lithium Battery Pack

When it comes to a lithium battery pack, there are four main components that play vital roles in its functionality and performance:

-

Battery Cell Type: The battery cell type refers to the specific configuration and chemistry of the cells used in the pack. The three common types are cylindrical battery cells, prismatic cells, and pouch cells. Each type has its own advantages and considerations, such as energy density, form factor, and manufacturing cost.

-

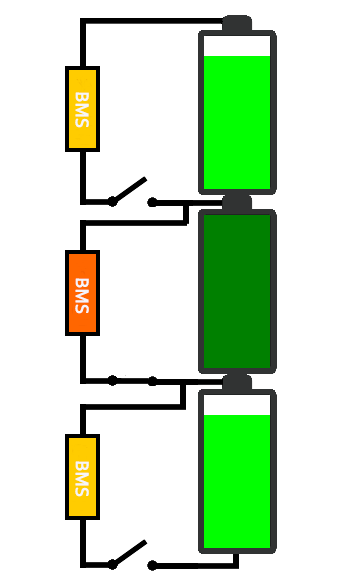

PCM or BMS (Protection Circuit Module or Battery Management System): The PCM or BMS is responsible for managing and protecting the battery pack. It performs essential functions such as short-circuit protection, over-charge protection, over-discharge protection, over-current protection, and temperature monitoring (NTC). Additionally, it monitors battery status parameters like State of Charge (SOC), State of Health (SOH), State of Power (SOP), and facilitates communication with the battery through protocols like CAN (Controller Area Network).

-

Battery Enclosure: The battery enclosure refers to the protective housing or casing that holds the battery cells and other components securely. Enclosures can be made of materials like PVC wrapping, plastic enclosures, or metal enclosures. PVC wrapping is commonly used due to its cost-effectiveness and versatility, often requiring minimal Minimum Order Quantity (MOQ).

-

Connector: Connectors play a crucial role in the battery pack, enabling the electrical connection between the battery and the device or system it powers. While connectors may not be the primary concern, they can contribute to the overall cost of the battery pack. Some connectors can be expensive, impacting the total battery cost.

Battery Cell

For lithium battery cells, we want to explain in detail from two perspectives: Cell Type and Battery Material.

A. Cell Type:

Lithium battery cells can be categorized into three main types: Pouch cells, Prismatic cells, and Cylindrical cells.

Prismatic or pouch cells, commonly known as lipo cells, find widespread use in electronic devices. These lightweight cells are found in our portable gadgets and are prevalent in RC Helicopters and Quadcopters. However, they may have higher Minimum Order Quantities (MOQ) of around 3,000 or 5,000 units per order.

Cylindrical cells like the popular 18650 or 26650 are extensively utilized in battery packs. These cells are readily available in the market with a wide range of pricing options, ranging from $0.5 to $4 per cell. Customized models of cylindrical cells usually have small MOQs, but it’s important to consider their cylindrical form factor, which may limit space utilization.

B. Battery Components:

The components used in battery manufacturing can vary among different factories, and the choice of raw materials plays a crucial role. It’s important to note that there can be significant pricing differences based on the raw materials used. Some battery cells may claim a capacity of 2200mAh, but they achieve this by sacrificing life cycle or overall performance. While they may have a higher capacity rating, their life expectancy may be considerably shorter, around 300 charge cycles, compared to the standard 500 cycles for normal cells.

Another critical consideration is the distinction between capacity-focused cells and discharge-focused (high drain) cells. Based on our experience, some manufacturers may attempt to use capacity-focused cells in battery packs that require high-discharge capabilities, such as in balance scooters. The reason for this is often cost-related, as capacity-focused cells are generally cheaper than discharge-focused cells. However, devices like balance scooters often require a C-rate of 3-5C, which exceeds the maximum capacity-focused cells can handle. In contrast, discharge-focused cells are designed to handle such high C-rate requirements, typically ranging from 5C to 20C.

It’s important to understand that there is no clear distinction between capacity-focused cells and discharge-focused cells, and their categorization ultimately lies in the hands of the manufacturer. Therefore, it becomes crucial to conduct your own testing to evaluate the performance and suitability of different battery cells for your specific application.

Takeaway: The classification of battery cells as capacity-focused or discharge-focused is not standardized and can vary among manufacturers. It is essential to thoroughly test and evaluate different cells to ensure they meet the specific requirements of your application, especially when it comes to high-discharge applications.

C. Battery Grade:

Battery cells undergo grading based on A, B, C, or further classifications such as A+, A-, B+, and B-. Let’s consider the example of Samsung 18650 2200mAh cells in mass production. Before being released to the market, each cell undergoes a final grading process. Cells with a capacity of 2200mAh and a life cycle of around 500 cycles are labeled as Grade A. Cells with a capacity below 2100mAh are labeled as Grade B, and cells with a life cycle of less than 300 cycles are categorized as Grade C. Please note that these numbers are for reference only, and for more professional advice, we recommend reaching out to our sales team.

Why does this grading occur? The answer is simple: not every cell is produced with an exact capacity of 2200mAh and 500 life cycles. There are variations in performance, with some cells exceeding 2400mAh and others falling below 1800mAh. Despite the high production control by cell manufacturers like Samsung, such variations are inevitable.

Battery cells are graded based on factors like capacity, life cycle, and sometimes appearance, using the categories of A, B, C, and D. However, it is important to note that there are no universally defined industrial standards for what constitutes Grade A or Grade B. The grading criteria can vary among manufacturers. Hence, the designation of a cell as Grade A is often just a marketing slogan without much practical significance. However, reputable branded cells tend to place greater emphasis on maintaining higher quality standards. Therefore, it is advisable to choose branded cells whenever possible.

Important Takeaway: When assembling battery packs with more than four cells, it is crucial to ensure that the cells used are of the same grade, preferably Grade A. Mixing cells of different grades increases the risk of shorter battery life or even the potential for explosion. This is not meant to scare you but rather to emphasize the importance of maintaining cell consistency and balance in battery packs.

Related: Wikipedia Battery Balancing

Consider the scenario where four cells with capacities of 2100mAh, 2200mAh, 2200mAh, and 1950mAh are being charged together. If the 1950mAh cell reaches full charge before the others, but the charger continues to supply energy based on the capacity of the remaining cells, there is a high risk of fire or explosion during the charging process. The greater the difference in capacity between cells, the higher the potential for disastrous outcomes.

Furthermore, it is essential to be cautious when purchasing batteries to avoid counterfeit or fake products. Opting for fake Samsung or Sony cells purely for the sake of a cheaper offer can lead to detrimental consequences for your customers and your company. Remember the recall story of Samsung Note 7, which caused significant harm and reputation damage. You certainly don’t want to face a similar situation, risking your business and potentially facing legal consequences.

D. Business Type:

Many buyers have the misconception that they should only deal directly with battery cell manufacturers. However, this perspective may not hold much practical significance. Instead, we recommend focusing on the professionalism and capabilities of the supplier you are engaging with, regardless of whether they are a cell maker or not.

Allow us to explain further to clear any confusion.

Let’s begin with a simple question: Who are the best lithium cell/pack manufacturers? Names like Samsung, LG, Sony, and Panasonic immediately come to mind. However, dealing directly with these giants may not be feasible for most buyers due to their high minimum order quantities (MOQ) of 500,000 units per order.

It’s a harsh reality.

This is also true for many Chinese cell makers who may not prioritize small-scale orders. Their operations revolve around maximizing machine utilization by running continuously 24/7. If accommodating a new model or fulfilling a small order disrupts their production flow, it is unlikely they will entertain such requests.

So, where does that leave you? You may find yourself dealing with third, fourth, or even fifth-level traders or manufacturers, rather than interacting directly with the cell makers.

Now, let’s circle back to the Samsung cell example. If a pack manufacturer cannot meet the massive MOQ of 500,000 units per cell type (not just for one month but for several months or years), they are forced to source from traders.

You can probably guess the answer when it comes to second-hand traders.

Feeling frustrated by not being able to engage directly with cell makers? The reality is that the supply chain involves various levels of intermediaries. Instead of fixating on whether you are dealing directly with a cell maker, focus on finding a reputable supplier with the necessary expertise and professionalism to meet your specific requirements.

Remember, the key is to partner with a supplier who understands your needs, provides reliable products, and offers exceptional service. Whether they are a cell maker, trader, or manufacturer, their ability to deliver quality battery solutions is what truly matters.